Need A Shower Renovation? Call the Best – DAD’s Construction!

If you need a shower renovation, you might be asking yourself “What exactly is a shower renovation?” A shower renovation is the complete removal of the existing shower, including fixtures, with a new shower being installed. All shower renovations are unique and rarely will any two be alike. The new shower does not need to replicate the old shower and rarely does. All shower renovations require a building permit.

Think of a shower as a swimming pool. A swimming pool is a complete watertight system with no seams. Like a pool, only a correctly installed shower with no seams will be watertight. Anything less and you will have problems.

There are eight shower configurations:

- Fully tiled shower over cement walls.

- Molded one-piece shower pan (aka base or receptor) with tile surround walls.

- One-piece fiberglass or acrylic shower.

- Two-piece shower using fiberglass or acrylic pan and single wall surround.

- Four-piece shower using separate fiberglass or acrylic pan and wall surrounds.

- Four-piece shower using fiberglass or acrylic base with solid surround wall panels.

- Shower pan liner with cement board walls and tile.

- Polyethylene membrane over cement board walls and tile.

Let’s take a look at each separately and consider the pros and cons of each.

Fully Tiled Shower Over Cement Walls

This is the best shower renovation system. It offers the greatest waterproofing, strength, and highest quality. These showers beautifully display your unique character and make any bathroom go from ordinary to extraordinary. Tiled showers create that charming, personal space for relaxation and release of tension. Tile creates harmony and helps settle you into a soothing peace after an exhausting day at work, chasing kids, or after an invigorating workout at the gym. A quality tiled shower will cost between $500 to over $800 per square foot. This does not include any repairs, framing, demolition, disposal, fixtures, enclosure, or accessories.

This is the best shower renovation system. It offers the greatest waterproofing, strength, and highest quality. These showers beautifully display your unique character and make any bathroom go from ordinary to extraordinary. Tiled showers create that charming, personal space for relaxation and release of tension. Tile creates harmony and helps settle you into a soothing peace after an exhausting day at work, chasing kids, or after an invigorating workout at the gym. A quality tiled shower will cost between $500 to over $800 per square foot. This does not include any repairs, framing, demolition, disposal, fixtures, enclosure, or accessories.

A tiled shower with cement walls will be level, plumb, and straight. This makes an enormous difference when tiling and installing the enclosure. Any other system and your tile will not be uniform, level, and corners true. The completed tile project will look and feel “off” and unbalanced. The enclosure will not be straight and look “not quite right.” The worse part is that any other system will fail prematurely and leak. Any other system will damage your home and possibly the health of you and your family.

Here are the important shower renovation points to consider when performing a fully tiled shower over cement walls:

- What is that funky smell that you just cannot seem to get rid of around the shower? Maybe you no longer notice the smell? Here is what creates the odor:

- After removing any old shower, regardless of type, the area under the pan is usually wet. Why? Most showers installed in tract homes are inexpensive economy systems. The drains begin leaking after a few years.

Showers with a fiberglass pan over concrete have drains that are usually not fully cemented around the perimeter. There is a 2 to 6-inch dirt circle around the drain. This is where the leaking drain water goes. The dirt is very rancid, smells like a sewer, and must be removed before the new tile shower is installed. Concreate is then poured in its place after allowing ample time for the dirt to dry.

Showers with a fiberglass pan over concrete have drains that are usually not fully cemented around the perimeter. There is a 2 to 6-inch dirt circle around the drain. This is where the leaking drain water goes. The dirt is very rancid, smells like a sewer, and must be removed before the new tile shower is installed. Concreate is then poured in its place after allowing ample time for the dirt to dry.- In similar fashion, fiberglass shower pans over wood floors also leak, creating mold, mildew, and rot. This must be removed with new wood structure and floor sheeting installed.

For those with a hot mop shower pan, these were likely never tested for leaks as required by building code. With new home tract construction, speed is everything. The object is to get the house built as cheaply and as quickly as possible – and sold for maximum price! The hot mop is typically a single layer system using the least amount of tar possible. Moreover, when the shower is tiled, little concern is given to protecting the hot mop in the pan. In addition, the drains are almost never correct. They use the wrong type of drain to save a few dollars. As moister gets in the pan, it does not flow into the drain, creating nasty smells and rot into the wood sub-structure.

For those with a hot mop shower pan, these were likely never tested for leaks as required by building code. With new home tract construction, speed is everything. The object is to get the house built as cheaply and as quickly as possible – and sold for maximum price! The hot mop is typically a single layer system using the least amount of tar possible. Moreover, when the shower is tiled, little concern is given to protecting the hot mop in the pan. In addition, the drains are almost never correct. They use the wrong type of drain to save a few dollars. As moister gets in the pan, it does not flow into the drain, creating nasty smells and rot into the wood sub-structure.

- After removing any old shower, regardless of type, the area under the pan is usually wet. Why? Most showers installed in tract homes are inexpensive economy systems. The drains begin leaking after a few years.

Your new tiled shower must have the following to ensure none of the above problems:

Plans and permits from the Building Department.

Plans and permits from the Building Department.- All concreate and/or wood repaired.

- New weep holes type drain installed.

- A 2-layer hot mop system. This comes from hot liquid tar, not out of a can from some Home Improvement Store. All seats, dams, and shower recesses must be hot mopped to ensure a strong waterproofing. After drying for 3 days, a pan test and inspection by the Building Department is required. Without this inspection, there is no guarantee or proof that your shower will not leak. Do not skip this step!

- Solid 2×12 wood blocking inside the base perimeter walls. This is required for a hot mop and to guarantee a strong, durable shower pan.

- Solid 2×12 wood blocking inside the perimeter walls for future hand bars (grab bars). If you do not do this, installing hand bars at a later date is a waste of time. They will not stay secure and you will likely cause yourself serious injuries. It is also required by building code.

- Cement the entire shower. Use a superior quality water proofing paper on the walls with galvanized lath (chicken wire). Ensure the paper and wire is correctly overlapped. Never use backerboards, cement board, drywall, or Polyethylene systems. They do not work! Yes, they are cheaper. However, you will pay a very steep price down the road to repair the damage they cause. See How Do You Remodel A Shower?

Molded One-Piece Shower Pan (aka base or receptor) with Tile Surround Walls

This is a 2-part shower renovation system: The pan and the tiled walls. A fiberglass shower pan costs about $175 to $600. An acrylic shower pan runs about $275 to $575. Both typically have a 1-year warranty. A cast iron pan costs about $775 to $1,300. Kohler Cast Iron Shower Pans have a lifetime warranty.

This is a 2-part shower renovation system: The pan and the tiled walls. A fiberglass shower pan costs about $175 to $600. An acrylic shower pan runs about $275 to $575. Both typically have a 1-year warranty. A cast iron pan costs about $775 to $1,300. Kohler Cast Iron Shower Pans have a lifetime warranty.

These molded fiberglass and acrylic pans reduce the price of a fully tiled shower by around $1,500 to $2,000. However, there is a significant drawback to these bases. They will fail and leak decades before the tile walls will experience any issues. Moreover, when the pan fails, cutting out the pan and replacing it with another pan or tile will make the situation worse! Please do not fall for this cheap gimmick! It will not, nor can it work! It will leak!

When a one-piece fiberglass or acrylic shower is removed (see immediately below), this is the system that usually replaces it. Provided the client wants a molded shower pan.

Molded fiberglass pans will flex and crack, especially around the drain. When this occurs, they will leak. Fiberglass chips easily. These pans are easily damaged. Acrylic pans, although stronger than fiberglass, also flex and will crack – typically around the drain. Here too, once cracked, acrylic pans leak.

One-piece molded shower pans can be very slippery. This can be dangerous for those with mobility concerns. Frankly, any age can fall and be injured.

Molded shower pans hold dirt, scratch, and stain easily. If you have one of these now, take a look at it. It likely looks dirty, dingy, and unsanitary.

One-Piece Fiberglass or Acrylic Shower

In this configuration, there is one complete piece. These one-piece shower units (or shower stalls) are installed prior to drywall, flooring, toilet, and sinks being installed when the house was originally built. These are also typically installed before the final enclosing third wall is built around it. The cost of a one-piece unit is in the range of $900 to $1,900.

In this configuration, there is one complete piece. These one-piece shower units (or shower stalls) are installed prior to drywall, flooring, toilet, and sinks being installed when the house was originally built. These are also typically installed before the final enclosing third wall is built around it. The cost of a one-piece unit is in the range of $900 to $1,900.

With few exceptions, one-piece systems have two installation options:

- Everything in front of the unit must be removed – the toilet, sink, flooring, and the drywall.

- Remove one of the short walls and slide the replacement tub/shower unit into place. Rebuild the short wall. This may require removing and then replacing the hot and cold-water lines along with the drain and vent stack. Moreover, this is not always possible if there is a narrow hall, exterior wall, or other bathroom adjacent to the 1-piece tub/shower. This second approach is not always a viable option.

This type of shower renovation system is very common in tract housing, condominiums, town homes, rental property, and apartments.

Two-Piece Shower Using Fiberglass or Acrylic Pan and Single Wall Surround

The shower pan and wall surround are installed separately. This is another method to replace a removed 1-piece shower. This sometimes eliminates the need to remove a third wall. However, the toilet, cabinet, and wall fixtures must be removed along with sufficient drywall to slide the new pan and surround into place. These cost about $1,100 to $1,600.

The shower pan and wall surround are installed separately. This is another method to replace a removed 1-piece shower. This sometimes eliminates the need to remove a third wall. However, the toilet, cabinet, and wall fixtures must be removed along with sufficient drywall to slide the new pan and surround into place. These cost about $1,100 to $1,600.

I have seen where other contractors have lifted and then forced the pan and “bent” the surround into place without removing the cabinet, toilet, drywall, etc. The results were less than spectacular.

The installer in this shower renovation scenario forces the pan and surround into place after cutting the supporting wood framing, weakening the wall. This always results in the structural integrity of the wall being damaged. The installer usually quickly makes a repair to the now cracked pan and surround and you are none the wiser. Except now you have a damaged shower system that will worsen over time. The hot and cold-water temperature variations along with body weight will cause the repair to fail. This usually happens within a few years. Long after your check clears. If someone falls or puts pressure against the area where the wood was removed, the surround will likely crack or break. It is a no-win situation – except for the installer who now has your money!

Four-Piece Shower Using Separate Fiberglass or Acrylic Pan and Wall Surrounds

The shower and wall surrounds can be purchased separately. The cost of these run about $600 to $1,400.

The shower and wall surrounds can be purchased separately. The cost of these run about $600 to $1,400.

In this scenario, the shower has 4 pieces; a pan and 3 separate wall surrounds. These are a terrible option. They will leak, causing dangerous and unhealthy mold growth in your walls. The seams are connected using a snap-and-pin system or glued in place using a construction adhesive. Some use a wedge and lock installation system.

These are the easiest systems to replace an existing shower system of any type. It is also the least expensive system. These are usually found in homes that are flipped, apartments, and rental properties.

Many contractors will use a hybrid of this shower renovation system to get the bathroom or shower remodel price down really low. They do this by removing only the old pan, leaving the original tile walls. Then, they install the new molded pan and simply install these panels over the existing tile.

Another variation to get the bathroom or tub/shower remodel price down super low is to have the pan sprayed with a fiberglass gelcoat. Then installing new panels over the old tile or fiberglass wall panels. In these two situations, the original walls remain. These two methods are the worst possible situations. Your house will be severely damaged by mold, rot, and mildew. Your health will also be compromised. Never use a four-piece tub/shower combination with or without removing the old wall tile or panels. It is cheap and very dangerous to your home and health! You will pay a very heavy future price.

Four-Piece Shower Using Fiberglass or Acrylic Base with Solid Surround Wall Panels

Solid wall surfaces include Onyx®, Swanstone®, and Corian®. These products use various forms of alumina trihydrate crystals and special polyester resins. These are high-end shower renovation products. The cost runs anywhere between $55 and $300 per square foot. All have very strong positive traits. These panels are available in a variety of colors and styles.

Solid wall surfaces include Onyx®, Swanstone®, and Corian®. These products use various forms of alumina trihydrate crystals and special polyester resins. These are high-end shower renovation products. The cost runs anywhere between $55 and $300 per square foot. All have very strong positive traits. These panels are available in a variety of colors and styles.

These products are extremely durable and easy to maintain and clean.

Onyx Shower Renovation

Onyx manufactures tub and shower wall panels along with shower pans (aka receptors or bases). They do not make tubs. They also make a generous line of accessories, sinks, countertops, and mosaic tile.

Onyx has the best warranty by a wide margin. It has a forever warranty. The Onyx Collection products are cast in cultured marble molds and have the look and feel of stone and granite. They are available in more than 70 colors in both matte and gloss finishes. Onyx has been around since 1985 (37 years).

Swanstone Shower Renovation

Swanstone has been making products since 1964 (58 years). Their website is very easy to use. Customers can order samples at no charge. They also have a wealth of Price Guides and Booklets on their website. It is available in 40 colors and a variety of finishes. They make shower pans, tubs, wall panels, and accessories. They also make countertops and sinks.

Color and texture are consistent throughout, with no surface coating to crack or chip. Compression molded, not cast, Swanstone will not crack or craze like other materials — and it is easy to maintain, since it will not mold or mildew. Five times stronger than other solid surfaces, Swanstone will not break, even when hit with a hammer.

Swanstone is heat resistant to 450°F – the best in the industry. Walls can handle steamer units. Swanstone is impervious to damage from common household culprits. Acetone will not etch it; cosmetics and beverages cannot permanently stain it. Swanstone is a major competing brand of Corian and benefited by the expiration of DuPont’s Corian patent.

Corian Shower Renoivation

Corian is made by DuPont. It has been around since 1967 (55 years). Corian is available in over 120 colors, a variety of finishes, and 3 thicknesses. It has a 10-year warranty. Products include shower and tub wall panels, sinks, and countertops. They also make textured walls that are truly unique.

Corian is non-porous, stain resistant, and has a seamless appearance. This can be repaired and it is renewable: Cuts and scratches can be buffed out with a Scotch-Brite pad or orbital sander. It is only heat resistant to 212°F, non-porous and does not need sealing. Corian is easy to clean and maintain.

Generally cheaper than quartz or granite countertops. However, re-sale value is less than granite, marble, or quartz. It can be dented and scratched as it is a softer surface (but repairable). It does not handle heat well. Hot pans can burn Corian (often repairable). Some cleaners and chemicals may cause discoloration.

From my experience, all wall panels become brittle with age. When we remove these panels in homes that are 25-40 years old, they break into very sharp pieces. Almost like glass. Although I have never heard of any wall panel failure, my concern would be in a seismic event. Since these panels are so heavy, if one were to come loose and fall, an adult or child could be seriously injured.

Shower Pan Liner with Cement Board Walls and Tile

A pan liner is made using polyvinyl chloride (PVC). It is 40mm thick and costs around $35.00 per piece. It is typically sold in 5-foot x 6-foot (30 square feet) pieces. This is by far the least expensive shower pan. A PVC liner is a very inexpensive way to tile a shower pan. Almost too good to be true (that’s because it is).

Take a look at the pictures of this product installed. Wherever there is lapping, a potential water problem exists. Although the corners (provided it is installed correctly) are folded, not cut, pathogens and organic material will fill these folds. When this happens, it travels up into your walls and begins eating your wood. Mold, mildew, and rot develops. Over years, it causes significant damage to your house and possibly your health.

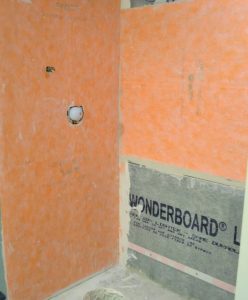

This shower renovation system almost always uses cement boards on the walls. Notice that these cement boards are

This shower renovation system almost always uses cement boards on the walls. Notice that these cement boards are  installed about 2-3 inches from the bottom of the shower pan. This leaves a gap between the liner and the cement board at the bottom. Over time, the moisture that collects in the pan cement will saturate the board. The cement board will soak up the moisture and travel up the wall. Moreover, pathogens and organic material will collect behind this bottom area and transition to the wood framing. Mold, mildew, rot, and termites develop. Over years, this will damage and destroy your wood walls and structure. This can also cause serious health issues for you and your family.

installed about 2-3 inches from the bottom of the shower pan. This leaves a gap between the liner and the cement board at the bottom. Over time, the moisture that collects in the pan cement will saturate the board. The cement board will soak up the moisture and travel up the wall. Moreover, pathogens and organic material will collect behind this bottom area and transition to the wood framing. Mold, mildew, rot, and termites develop. Over years, this will damage and destroy your wood walls and structure. This can also cause serious health issues for you and your family.

You may save money initially on your shower renovation, however; the costs you will pay down the road to fix your house will greatly exceed any savings.

Polyethylene Membrane Over Cement Board Walls and Tile

Commonly referred to as Schluter®-KERDI. This is a pliable sheet-applied waterproofing membrane and vapor-retarder designed for the direct application of tile. It is applied over cement board or Schluter®-KERDI-BOARD. Tile is then applied directly over the Schluter®-KERDI product.

Commonly referred to as Schluter®-KERDI. This is a pliable sheet-applied waterproofing membrane and vapor-retarder designed for the direct application of tile. It is applied over cement board or Schluter®-KERDI-BOARD. Tile is then applied directly over the Schluter®-KERDI product.

KERDI is 8-mil-thick. It is sold in rolls ranging from 54 square feet (About $125) to 323 square feet (about $400). In recent years, this process has become very popular with tile installers. It is fast and cheap. As with anything, the combination of these two is ripe for concern.

The very definition of Fast and Cheap makes one nervous. The definition is: Design and build something quickly and cheaply, but it will not be of high quality or durability. Why? Because quick and cheap is a house of playing cards. In other words, success requires well thought out planning, careful execution, using high quality materials and people. Anything else and it will fail.

This shower renovation system, just like those using molded pans and cement boards, are not seamless. It’s like trying to hold water in a glass that was broken and glued back together. It is the same thing. With seams you will have problems. I cannot stress this enough.

Final Note on a Shower Renovation

Many tile installers and contractors will not remove and replace the old shower pan in a shower renovation. Rather, they leave the old pan and install the new tile over it. This is how they get the price down even lower or simply rip you off! Notice in the picture the red circle I drew. What you are looking at is a drain spacer. These drain spacers are installed directly over the old drain. The spacer is the thickness of the new tile.

Many tile installers and contractors will not remove and replace the old shower pan in a shower renovation. Rather, they leave the old pan and install the new tile over it. This is how they get the price down even lower or simply rip you off! Notice in the picture the red circle I drew. What you are looking at is a drain spacer. These drain spacers are installed directly over the old drain. The spacer is the thickness of the new tile.

This is grossly incorrect. All old shower pans must be removed and reinstalled with a new hot mop. The drain must also be reinstalled. From our earlier discussions, you learned almost all shower leaks originate from the drain and/or incorrectly installed shower pans. There are no shortcuts and there are no other options to ensure your new shower pan will not leak. Don’t be fooled by a low price and make sure the entire shower base/pan is replaced!

Shower Renovation Summary

Go back to the second paragraph at the beginning of this paper. A shower is a swimming pool. A swimming pool is a complete watertight system with no seams. Any shower constructed using any method other than a Fully Tiled Shower over Cement Walls will fail prematurely, damage your home, and has the potential to harm you and your family’s health. If you are interested in shower renovation costs, please see the article “how much to replace a shower” and learn important information on shower replacement costs.

Always Hire a Reliable and Dependable Contractor to Remodel your Bathroom

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements. Rest assured that we will provide you with a detailed, by line-item contract. We will make sure that the contents of this agreement are properly and clearly communicated to you. If you have questions or need updates regarding your project, we will always answer your inquiries.

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements. Rest assured that we will provide you with a detailed, by line-item contract. We will make sure that the contents of this agreement are properly and clearly communicated to you. If you have questions or need updates regarding your project, we will always answer your inquiries.

How Can I Receive More Information?

If you would like more information on enjoying the best bathroom, kitchen, and interior remodeling experience in Orange County, call Dan at (949) 380-0177 or at dan@dadsconstruction.com for a free in home consultation. DAD’s serves all of South Orange County California. This includes Lake Forest, Mission Viejo, Foothill Ranch, Portola Hills, Ladera Ranch, Irvine, San Clemente, Dana Point, San Juan Capistrano, Rancho Santa Margarita, Coto de Caza, Dove Canyon, Laguna Niguel, Laguna Hills, Laguna Beach, Newport Beach, and Aliso Viejo.

Showers with a fiberglass pan over concrete have drains that are usually not fully cemented around the perimeter. There is a 2 to 6-inch dirt circle around the drain. This is where the leaking drain water goes. The dirt is very rancid, smells like a sewer, and must be removed before the new tile shower is installed. Concreate is then poured in its place after allowing ample time for the dirt to dry.

Showers with a fiberglass pan over concrete have drains that are usually not fully cemented around the perimeter. There is a 2 to 6-inch dirt circle around the drain. This is where the leaking drain water goes. The dirt is very rancid, smells like a sewer, and must be removed before the new tile shower is installed. Concreate is then poured in its place after allowing ample time for the dirt to dry. For those with a hot mop shower pan, these were likely never tested for leaks as required by building code. With new home tract construction, speed is everything. The object is to get the house built as cheaply and as quickly as possible – and sold for maximum price! The hot mop is typically a single layer system using the least amount of tar possible. Moreover, when the shower is tiled, little concern is given to protecting the hot mop in the pan. In addition, the drains are almost never correct. They use the wrong type of drain to save a few dollars. As moister gets in the pan, it does not flow into the drain, creating nasty smells and rot into the wood sub-structure.

For those with a hot mop shower pan, these were likely never tested for leaks as required by building code. With new home tract construction, speed is everything. The object is to get the house built as cheaply and as quickly as possible – and sold for maximum price! The hot mop is typically a single layer system using the least amount of tar possible. Moreover, when the shower is tiled, little concern is given to protecting the hot mop in the pan. In addition, the drains are almost never correct. They use the wrong type of drain to save a few dollars. As moister gets in the pan, it does not flow into the drain, creating nasty smells and rot into the wood sub-structure.