How Do You Remodel a Shower?

Recently, I was visiting a customer for a bathroom remodel in Irvine, California. She asked me if there was more than one way to remodel a shower. If yes, which is the best? So, how do you remodel a shower?

When considering how to remodel a shower, there are 6 primary methods:

- Green board drywall.

- Cement board.

- Polyethylene.

- Polystyrene.

- Polyvinyl.

- Mortar.

A shower is fundamentally a mini swimming pool. All tile and grout permeate moisture. In other words, regardless of tile or grout quality or sealers used, all tile and grout will absorb moister. This moister can, over time, penetrate beyond the tile and grout. Using the correct installation method ensures moister will not pass through the underlayment barrier. The most important part of any tile project is the preparation of the tiles sub-surface (underlayment). The sub-surface is what’s behind the tile keeping it strong, durable, and water resistant. As with anything, the foundation is always the key to safety, quality, and durability.

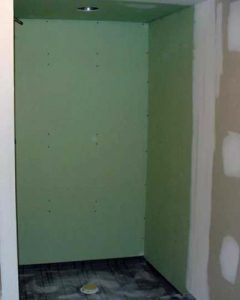

Greenboard Drywall

This is perhaps the worse method of all. Why is this? Drywall (gypsum board/sheetrock) crumbles and falls apart when it gets wet. Installing a product like this when you remodel a shower is a bad idea.

Many years ago, this was a fairly common and acceptable practice. When first introduced, greenboard drywall was marketed as the ideal product for wet applications. This included showers, bathtubs, steam rooms, etc. It’s moisture and mold-resistant properties made it an ideal and super inexpensive product. As time passed, it became apparent that, although well intentioned, was a bad idea.

These systems failed as they became wet. As a result, homes were damaged due to moisture, mold, and rot. This type of application is now illegal and not to code.

It really is a bad idea and can cause destructive damage to your home. This system can also be extremely harmful to your health and safety. It’s the least expensive way to tile a shower. However, it’s also the worst.

Cement Boards

Cement boards are a combination of cement and reinforcing fibers. These 1⁄4 to 1⁄2 inch thick 3 by 5 foot sheets are typically used as a backing board for tile installations. They are nailed or screwed to wood or steel studs to create a substrate for vertical tile surfaces.

The most common are HardiBacker®, Durock®, and WonderBoard®. Although preferred by many tile installers and contractors for its ease and speed of installation and lower cost, they will leak – I’ve seen it myself. The problem? Look at the picture.

What do you see? You see lots of seams, nail, and screw penetrations. Something you can’t see is that the walls are not plumb and square because these panels are installed directly over the wall studs. When the tile and glass enclosure are installed, this becomes visible as the finished product has an “off” and unpolished appearance.

Polyethylene Sheets

Polyethylene is a waterproofing layer that protects moisture-sensitive substrates. This type of system uses sheets of polyethylene. The seams are covered using an unmodified thin-set mortar or other suitable trowel-applied waterproofing materials. Common names are Schluter®-Kerdi Waterproofing Membrane and Schluter® Systems Kerdi. This product comes in rolls and is applied directly over drywall or cement board.

Using thin-set mortar, tile can be applied directly over polyethylene. Prior to installing the tile, all the seams receive a coating of thin-set mortar. Shower drain and valve openings are covered using prefabricated polyethylene seals. These too are applied using thin-set mortar.

Using thin-set mortar, tile can be applied directly over polyethylene. Prior to installing the tile, all the seams receive a coating of thin-set mortar. Shower drain and valve openings are covered using prefabricated polyethylene seals. These too are applied using thin-set mortar.

This system is becoming increasingly popular with tile installers and contractors. Why? Like its cement board cousins, its ease and speed of installation and lower cost are great selling points. What’s the reality? Anything with a seam can fail. Have you ever seen a swimming pool with a seam?

Polystyrene Foam Panels

Schluter®-KERDI-BOARD panels come in eight different thicknesses. It is a multifunctional tile substrate and building panel. These extruded polystyrene foam panels are designed to replace solid backing panels (i.e., gypsum board, cement backer board). Can you imagine the weakness and reliability of 1/2-inch foam panel walls behind your tile? How about the shower dam and pony walls? These are prefabricated hollow sections of foam! How strong and durable is this?

Schluter®-KERDI-BOARD panels come in eight different thicknesses. It is a multifunctional tile substrate and building panel. These extruded polystyrene foam panels are designed to replace solid backing panels (i.e., gypsum board, cement backer board). Can you imagine the weakness and reliability of 1/2-inch foam panel walls behind your tile? How about the shower dam and pony walls? These are prefabricated hollow sections of foam! How strong and durable is this?

Using thin-set mortar, tile can be applied directly over these foam panels (they contain no cement). Prior to installing the tile, all the panel seams, corners, and screw attachments are covered using 5-inch wide by 5mm (about 3/16 inch) thick strips of Polyethylene using thin-set mortar.

According to the manufacturer, these panels are “impact-resistant” and waterproof. This system is also becoming increasingly popular with tile installers and contractors. Why? Like its cement board and polyethylene cousins, its ease and speed of installation and lower cost are great selling points. What’s the reality? Anything with a seam or hole can and will fail. Returning to the pictures, look at all patched corners, seams, and holes. Does this look like a secure, waterproof system to you?

Polyvinyl Chloride (PVC)

A pan liner is made using polyvinyl chloride (PVC). It is 40mm thick and costs around $35.00 per piece. It is typically sold in 5-foot x 6-foot (30 square feet) pieces. This is by far the least expensive shower pan. A PVC liner is a very inexpensive way to tile a shower pan. Almost too good to be true (that’s because it is).

A pan liner is made using polyvinyl chloride (PVC). It is 40mm thick and costs around $35.00 per piece. It is typically sold in 5-foot x 6-foot (30 square feet) pieces. This is by far the least expensive shower pan. A PVC liner is a very inexpensive way to tile a shower pan. Almost too good to be true (that’s because it is).

Take a look at the pictures of this product installed. Wherever there is lapping, a potential water problem exists. Although the corners (provided it is installed correctly) are folded, not cut, pathogens and organic material will fill these folds. When this happens, it travels up into your walls and begins eating your wood. Mold, mildew, and rot develops. Over years, it causes significant damage to your house and possibly your health.

This system almost always uses cement boards on the walls. Notice that these cement boards are installed about 2-3 inches from the bottom of the shower pan. This leaves a gap between the liner and the cement board at the bottom.

This system almost always uses cement boards on the walls. Notice that these cement boards are installed about 2-3 inches from the bottom of the shower pan. This leaves a gap between the liner and the cement board at the bottom.

Over time, the moisture that collects in the pan cement will saturate the board. The cement board will soak up the moisture and travel up the wall. Moreover, pathogens and organic material will collect behind this bottom area and transition to the wood framing. Mold, mildew, rot, and termites develop. Over years, this will damage and destroy your wood walls and structure. This can also cause serious health issues for you and your family.

You may save money initially, however; the costs you will pay down the road to fix your house will greatly exceed any savings.

Lath and Mortar

|

|

|

|

This process ensures a high quality, long lasting, and durable shower. First, we start with a 100% integrity hot mop system using 4 layers of asphalt and 3 layers of 15 lb. felt. Second, DAD’s installs their proprietary tile underlayment. This is a water-resistant system consisting of a vapor retarder, galvanized steel lath, and Portland cement mixture. Third, tile is installed using a fortified polymer-modified high-grade mortar. Forth, high strength grout with the highest stain resistance is used. Lastly, all tile and grout are sealed using a premium penetrating sealer offering maximum protection.

This system is an extremely effective moisture vapor and stain retarder that is very strong, durable, and allows for plumb, square, and level walls. Lath and mortar is the only system that has proved itself for decades. There are no seams and creates the required “swimming pool” to keep water from escaping into the homes wall and floor structures. Over the last 20 years, other products and systems promising similar results at less cost and faster installation have been introduced. None have enjoyed the success of lath and mortar. There is simply no substitute for a lath and mortar tile installation.

Unlike the other systems discussed in this article, I’ve never seen a properly performed mortar system leak, crack, or deteriorate over time. I’ve removed countless mortar systems that were 50 plus years old and still looked great with no water vapor damage or cracks in the tile. It works – and it passes the test of time.

When Remodeling Your Shower, Don’t Make This Mistake.

This is an example of a shower remodel using methods other than lath and mortar. How long after the original remodel did this take? It only took 5 years for this level of destruction.

This is an example of a shower remodel using methods other than lath and mortar. How long after the original remodel did this take? It only took 5 years for this level of destruction.

You can easily see there was no hot mop. It’s also evident that the shower pan and shower itself used a sheeting product. Don’t believe hype and a low price!

The cost of the original shower remodel, repairing the damage, and then doing the job right the second time, far exceeded what it would have cost to do the shower correct the first time. There was no savings whatsoever – only lots of extra costs and frustration. Do it right the first time and save big!

Always Hire a Reliable and Dependable Contractor to Remodel your Shower

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements. Rest assured that we will provide you with a detailed, by line-item contract. We will make sure that the contents of this agreement are properly and clearly communicated to you. If you have questions or need updates regarding your project, we will always answer your inquiries.

Always work with a trustworthy contractor like DAD’s Construction. We are experts in bathroom remodeling who can manage projects in an efficient manner. DAD’s Construction will do everything to minimize the possibility of change orders. Our team will make sure we have all the necessary information to prepare a proposal that meets your requirements. Rest assured that we will provide you with a detailed, by line-item contract. We will make sure that the contents of this agreement are properly and clearly communicated to you. If you have questions or need updates regarding your project, we will always answer your inquiries.

How Can I Receive More Information on Remodeling my Home?

If you would like more information on enjoying the best bathroom, kitchen, and interior remodeling experience in Orange County, call Dan at (949) 380-0177 or at dan@dadsconstruction.com for a free in home consultation. DAD’s serves all of South Orange County California. This includes Lake Forest, Mission Viejo, Foothill Ranch, Portola Hills, Ladera Ranch, Irvine, San Clemente, Dana Point, San Juan Capistrano, Rancho Santa Margarita, Coto de Caza, Dove Canyon, Laguna Niguel, Laguna Hills, Laguna Beach, Newport Beach, and Aliso Viejo.